Workforce Development for an Autonomous Future at Anglo’s Quellaveco Mine

20 December 2019Located in the Moquegua region in the south of Peru, Quellaveco is one of the world’s largest undeveloped copper deposits. Part of the mine plans are to transition to autonomous haulage systems, and Quellaveco will utilize simulation-based training and workforce development solutions from Immersive Technologies to improve the efficiency of new operator training, ensuring its long-term productivity.

Immersive Technologies’ Experience Centers – Shaping New Leaders in Mining

31 October 2019Immersive Technologies has recently made available to the mining industry “Experience Centers” through its five largest offices world-wide, with the primary purpose being to demonstrate workforce optimization solutions, while sharing knowledge and best practices with mining industry professionals.

Byrnecut partners with Immersive Technologies to develop a world class blended learning training center

27 September 2019Byrnecut, in partnership with Immersive Technologies, have set a new standard in workforce training solutions with the success of its Perth based technical training center. Byrnecut are now set to achieve measurable in-field cost reductions, productivity gains and safety improvements via changes in equipment operator behavior due to 350 staff coming through the center in the past 9 months of operation.

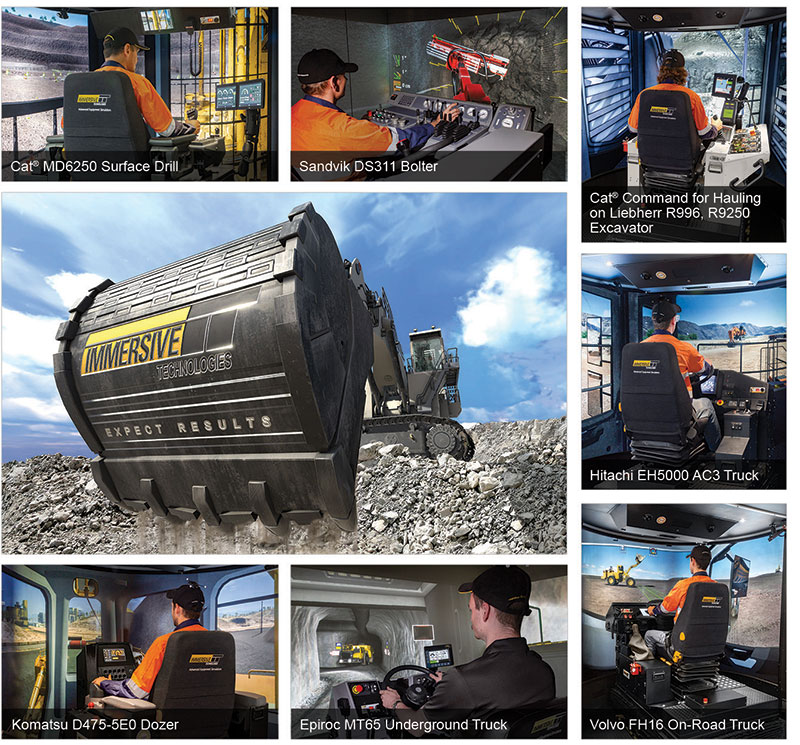

Multi-OEM Strategy: Immersive Technologies Powers Ahead for Superior Industry Support.

9 July 2019Immersive Technologies has engaged in an unprecedented level of mining machine simulator development for a diverse range of Original Equipment Manufacturers (OEM) over the past year. This is set to continue with projects underway for new and existing customers to build simulators for heavy machinery manufactured by Belaz, Caterpillar, Epiroc, Hitachi, Iveco, Komatsu, Liebherr, MACK and Volvo.

Komatsu to Acquire Mining Workforce Optimization Specialist, Immersive Technologies.

14 June 2019Komatsu Ltd. (President and CEO: Hiroyuki Ogawa) (TYO:6301) (hereafter “Komatsu”), through its wholly owned subsidiary in Australia, has agreed to acquire global mining technology and workforce optimization firm Immersive Corporation Pty. Ltd. (“Immersive Technologies”), which specialises in increasing mine profitability by optimizing the safety and productivity of equipment operators, on the condition that all necessary procedures for closing are completed.

Mines in Russia & CIS Rapidly Adopting Immersive Technologies Workforce Development Solutions

30 May 2019The proportion of global mining equipment being deployed in Russia is on the rise, 22% in 2018, compared to 9% in 2012, with regional growth of 13% over the past six years. As a result, the industry is demanding more skilled personnel. Mining companies in the region are turning to Immersive Technologies to deliver tailored workforce development solutions, proven to achieve safety and productivity improvements throughout all stages of the mining cycle.

Training Operators for Excellence – The Ok Tedi Way

29 April 2019Situated in Papua Guinea, the Simulator Training Center at The Ok Tedi Mine is living up to its commitment to develop their most valuable resource – employees. The company says since 1982 more than 10,500 employees have undertaken education and training and the simulator training center is proving to be a valuable asset in their training mix.

Immersive Technologies Recognizing Excellence in Mining Business Improvement

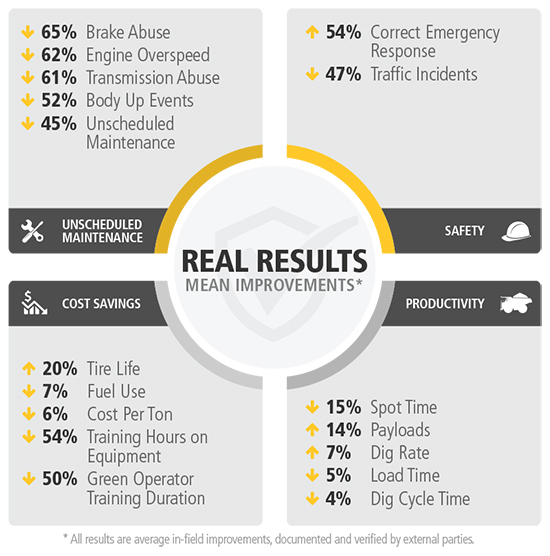

1 April 2019Immersive Technologies is pleased to announce the winners of the Global Business Improvement Award 2018. Marking the tenth year in which Immersive Technologies recognizes the most outstanding real results achieved by mining companies utilizing simulation as a key driver in the business improvement process.

Immersive Technologies Simulator Growth Drives Significant Customer Results in North America

27 February 2019The installed base of Immersive Technologies mining simulators in North America has seen consistent growth since the deployment of the first-generation units in the early 2000’s. Today, early adopters are upgrading their technology to the latest models while new customers are coming onboard at an accelerating rate. North American customers are increasingly obtaining quantified results in targeted areas such as lower spot times, higher dig rates and reduced machine abuse events caused by operator actions.

Immersive Technologies Identifies the Key Drivers Impacting Senior Mining Professional’s Customer Experience

04 February 2019Quantifiable return on investment is at the top of factors impacting mining customer experience and technology investment decisions. Immersive Technologies surveyed over 100 senior mining professionals across Australia, Africa, Europe, Asia, North America and South America to determine which variables drive a positive experience for miners in the introduction of new technologies.