Immersive Technologies Provides Autonomous Training Solution for Rio Tinto’s Gudai-Darri Mine

Having pioneered automation for over a decade, Rio Tinto is furthering their autonomous haulage footprint at their new Gudai-Darri Iron Ore mine in Western Australia, which will operate Caterpillar autonomous trucks equipped with Cat® MineStar™ Command for Hauling system.

Planned to be one of the world’s most automated mines, Gudai-Darri will utilize simulation-based training solutions from Immersive Technologies to address the workforce development challenges within autonomous haulage operations with a focus on improving the safety and efficiency of their operator workforce.

Utilizing advanced simulation systems from Immersive Technologies for over 17 years, Rio Tinto understands the value of investing in Immersive Technologies simulators for operator capability development, including equipment productivity and reliability initiatives. These initiatives have been supported within Rio Tinto Iron Ore for many years.

“This is an important component of our comprehensive training program for AHS, which includes supporting new team members as well as upskilling existing employees,”

“Gudai-Darri will be one of the world’s most technologically advanced mines. Preparations are well under way to ensure its workforce is ready to take on the high-tech jobs on offer.”

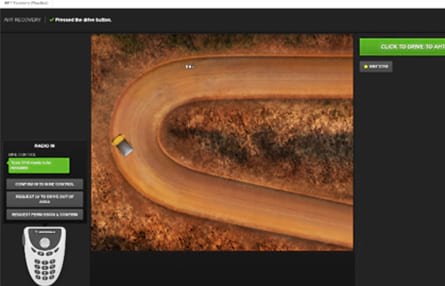

Focused on capability development in the usage of the autonomous system, Rio Tinto partnered with Immersive Technologies to provide a solution to support the mine readiness schedule and objectives. Specific training products include a platform which simulates a CAT 6060 Excavator, CAT D10T Dozer and CAT 18M Grader. All simulator modules are equipped with an autonomous system panel and provide a safe and effective environment for training by allowing learners to operate their equipment while interacting with the autonomous trucks and managing their work areas as required.

The simulator solution is complimented by machine pre-start inspection software which provides a detailed visualization of equipment components, including autonomous components fitted to machines. Additionally, a Virtual Classroom product hosts complex autonomous procedures that immerses learners in a safe and repeatable virtual environment which enables the development of deep knowledge and muscle memory of operational procedures.

“Immersive Technologies is at the forefront of Workforce Development for Autonomous Haulage mining operations with deployments of simulation-based training solutions in more than 17 autonomous sites globally, by utilizing blended learning systems, simulation and human performance analytics our solutions are preparing the workforces of the future.”

###

About Immersive Technologies

Immersive Technologies is the world’s largest, proven and tested supplier of surface and underground Advanced Equipment Simulators to the global mining industry. The company has achieved this unique position by focusing on its mission to increase Customer profitability by optimizing the safety and productivity of their operators. Immersive Technologies’ Advanced Equipment Simulators are helping hundreds of mining companies around the world to increase their equipment operators’ safety and site profitability through effective simulation training.

With advanced simulator modules deployed in 54 countries, Immersive Technologies is dedicated to provide outstanding service. To deliver on this commitment the company has customer sales and support offices located close to its customers in Perth and Brisbane Australia, Salt Lake City USA, Fort McMurray, Vancouver Canada, Estado de México Mexico, Lima Peru, Santiago Chile, Belo Horizonte Brazil, Bochum Germany, Johannesburg South Africa, Jakarta Indonesia, Kolkata India and Moscow Russia.

Immersive Technologies has the global mining experience, innovative technology, product range, industry endorsement, proven support commitment and industry vision to partner with you to ensure your simulator training solution delivers the significant results you expect.